Phase IV Wireless Motor Sensor For Predictive Maintenance – Leap Sensors

$ 699.00

Description

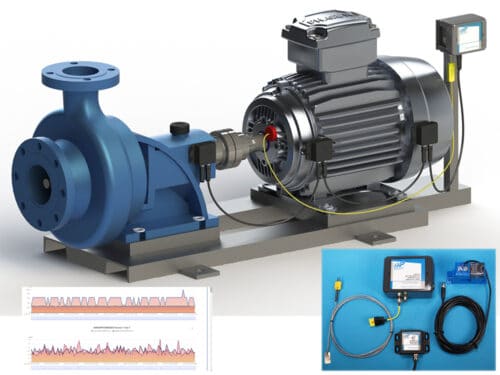

This unique motor sensor combines 3 different sensors in one multi-sensor node: temperature, vibration, and electrical current. Get continuous remote monitoring of these key predictors of motor failure. Receive alerts via text, email, or phone. Avoid costly downtime and gain operating insight.

Features

- Monitors the top 3 predictors of impending motor failures.

- Motor vibration monitoring sensor detects maximum and average vibration on 3 axes to detect upward trends or spikes in vibration.

- Multiple vibration modules may be daisy-chained together on one CAN bus that goes to the device node.

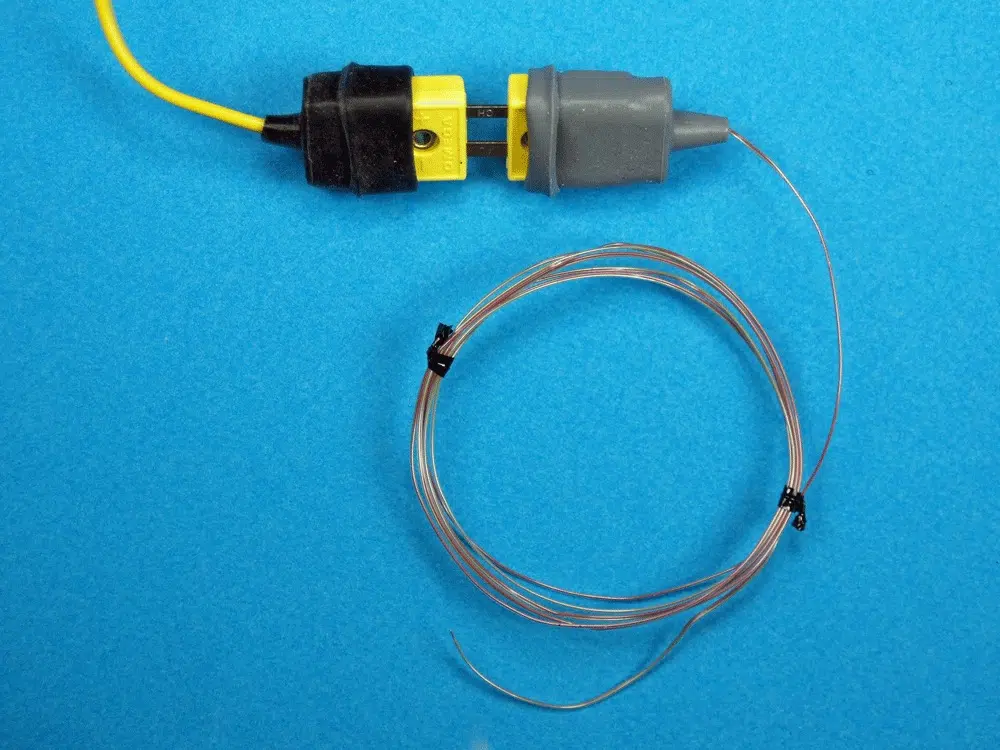

- Motor temperature monitoring sensor (thermocouple) mounts on the motor or gearbox to detect over-heating.

- Motor current monitoring sensor (amp clamp) detects increased electrical current to motors to detect overloads.

- Motor vibration monitoring sensor detects maximum and average vibration on 3 axes to detect upward trends or spikes in vibration.

- Fast and easy to install.

- Magnetic or screw mounts for temperature and vibration sensors.

- The amp clamp is a “split core” – allowing it to quickly install around a wire without disconnecting it.

- Standard monitoring scenario: Sensor transmits readings every 15 minutes.

- Temperature alerts are typically set based on normal readings.

- Electrical current alerts are typically set above normal readings.

- Vibration is sampled at 5 kHz on 3 axes for a few seconds in the range of 0 to 8Gs.

- The data is edge-processed on board the sensor using proven methods where a change in trend is indicative of an impending failure.