These wireless temperature sensors are part of the Leap Sensors® wireless remote industrial monitoring system. It is THE system designed from the ground up to meet the specific, challenging needs of industrial & commercial users. Designed to withstand extreme high and low temperatures. Get better process control, failure prevention, safety improvement, automated auditing. Make the leap to the Industrial IoT.

- Long-life battery (5-8 years, depending on application).

- Track remote pressure sensors and more (temperature, vibration, amp, humidity, etc.).

- Multiple sensors per module keep cost down.

- Quick 5 minutes or less install. Alerts are sent via mobile device, laptop, or other cellphone.

Click Images to View Product Details

- Long-life battery (up to 7 years, depending on application).

- Monitor humidity and more – temperature, vibration, amp, etc.

- Multiple sensors per transceiver node keep cost down.

- Easy to install in 5 minutes or less. Receive alerts via cellphone, laptop, or other mobile device.

Click Images to View Product Details

- Long-life battery (up to 7 years, depending on application).

- Monitor temperature and more – vibration, amp, humidity, etc.

- Multiple sensors per transceiver node keep cost down.

- Easy to install in 5 minutes or less. Receive alerts via cellphone, laptop, or other mobile device.

Click Images to View Product Details

- Long-life battery (up to 7 years, depending on application).

- Track temperature and more (vibration, amp, humidity, etc.).

- Multiple sensors per transceiver node decreasing costs.

- Quick 5 minutes or less install. Alerts are sent via mobile device, laptop, or other cellphone.

Click Images to View Product Details

- Long-life battery (up to 7 years, depending on application).

- Monitor humidity and more – temperature, vibration, amp, etc.

- Multiple sensors per transceiver node keep cost down.

- Easy to install in 5 minutes or less. Receive alerts via cellphone, laptop, or other mobile device.

Click Image to View Product Details

Frequently Asked Questions

- One Leap transceiver node can integrate multiple sensors of different types.

- Transceiver nodes arrive preconfigured.

- High-temperature monitoring options.

- The ability to convert almost any standard industrial sensor to wireless.

- Option to host the software inside the gateway.

- Multiple installation options for the Leap software.

- Integrated bicolor LED indicates the wireless connection status.

- Advanced IP-based system for sophisticated sensing and data-passing.

- Keep your sensor electronics safe from unexpected voltage surges.

- Get actionable data, not “Big Data.”

Phase IV has a variety of product offerings to include a Production Counter and Downtime Tracker Sensor.

When using these Leap Systems, you will be able to see exactly how shift changes and breaks impact your operational efficiency so that you can better plan for materials and labor for production rate.

Yes. The user manual shows how to connect the wires from the standard pressure sensor to the spring-loaded terminal block inside the enclosure.

The Leap transceiver node can support one 4-20 mA sensor and three 0-10V sensors. Make sure to set the min and max values in the configuration screen along with the unit of measure for the pressure.

Yes. For differential pressure, the Leap transceiver node calculates and sends the differential pressure over so that alerts may be easily be created in the Leap Sensor Manager software on the differential pressure reading.

Yes. A powerful battery inside the enclosure can supply 12V or 23VDC to the external sensor.

The user will configure the wireless transceiver node to wake-up every “X” minutes and take readings. Typically this is every 15 minutes.

The vibration sensor is activated and it runs for 3 seconds – taking readings on the X, Y, and Z axis at 5000 Hz on each axis.

The 45,000 vibration data points are then edge processed into metrics that are proven to indicate problematic changes in machine vibration. The X and Y axis are combined to report a “radial” or “rotating” direction. The Z axis is used to report the axial vibration that is parallel with the motor shaft.

The data is then edge processed into metrics for radial and axial vibration.

RMS acceleration weights the higher frequencies – friction, rubbing, grinding

RMS velocity weights the lower frequencies – misalignment or fatigue, unbalance, belt issue, poor mounting

Peak acceleration will detect serious impact forces such as bearing defects and chipped gear teeth

Crest Factor – Instability usually from impulses

One, or all, of these vibration metrics will typically increase from its baseline level to 2X normal baseline levels when failure happens. Alerts are typically set at 1.5X baseline levels.

werful battery inside the enclosure can supply 12V or 23VDC to the external sensor.

Yes. Talk to one of our experts to find a good first-application to try a wireless sensor. We will work with you to configure a proof of concept system for you that will be low-cost and easy to install. We will provide a detailed quote with photos and an estimated ROI that you can share with the purchase decision-maker.

Also, ask for a log-in to our demonstration system to give the system a try over the internet.

After a great first experience, the Leap system can support every type of industrial use case imaginable.

Typically, the battery will last approximately 3 to 5 years in a monitoring application where the transceiver node has multiple sensors.

Yes. This node can support up to 16 vibration nodes (on one daisy-chained cable). Each of these vibration nodes has a temperature sensor also.

There is also an option to add one or two thermocouples and one to three electric current transformers. Contact us to talk to an expert.

A Range Extender can be used, if needed, to pass the signal from a far-away sensor node.

The Leap transceiver node can support multiple temperature sensors of different types including:

- 2-wire and 3-wire PT100s and PT1000s.

- Thermocouples of every type.

- Digital temperature sensors

- Thermistors (less common)

The wires to the temperature sensor can be integrated with an IP67 M8 connector or the cable can be run through a metal IP67 cable gland and attached to the spring-loaded terminal block inside the enclosure.

Yes. We can verify them against a NIST traceable temperature standard and supply a certificate of conformance to that NIST traceable standard.

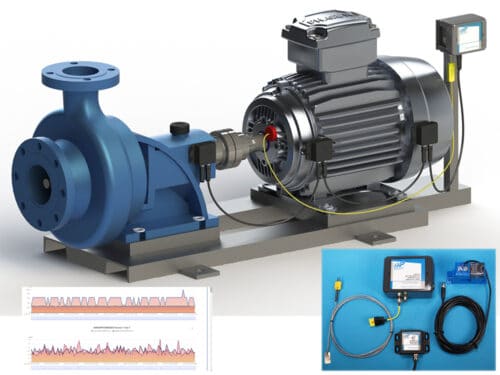

Using wireless sensors for motor condition monitoring is one way to enact predictive maintenance to keep equipment running at optimally at all times. Motors give indications of issues weeks before they quit. The key is to monitor and detect them early enough.

Three main indicators of approaching motor failure:

- Temperature

- Vibration

- Electrical Current

Wireless Motor Sensors by Phase IV Leap Sensors is the only sensor on the market that combines simple continuous monitoring of the three main indicators of impending motor failure.

Proudly Serving

- International Paper (Springfield)

- Georgia Pacific (Wauna, Toledo)

- Avangrid Power (Klamath Falls)

- Roseburg Forest Products (All locations in the NW)

- Sierra Pacific Industries (All locations in the NW)